Category

Triangle Valve, Plumbing Accessories, Angle Valve, Faucet, Faucet Accessories, Hardware, Pipe Valve, Water Valve Switch

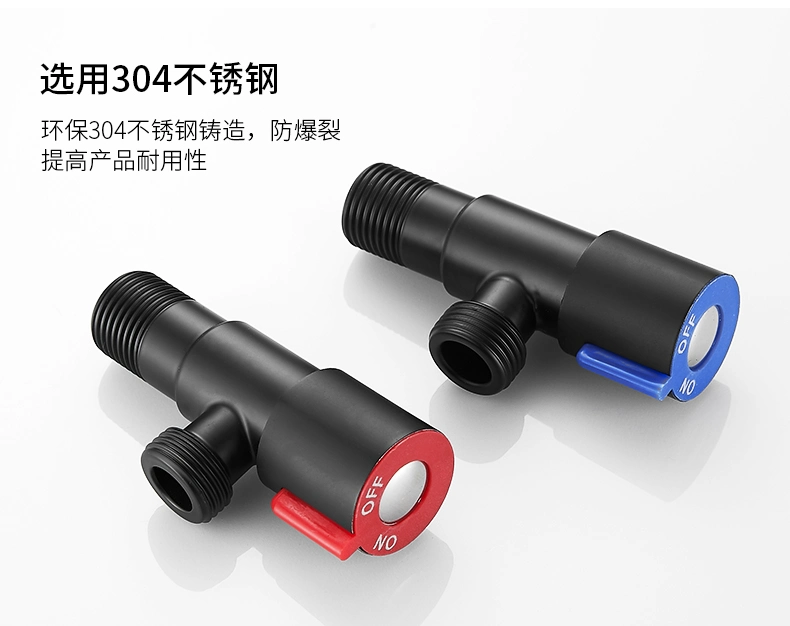

Note: the dimensions are for reference, and the details are subject to the real object SUS304 angle valve: size and spec

Basic Info

| Model NO. | XS-L304 |

| After-sales Service | Three Guarantees of Product Quality |

| Warranty | 5-Year Quality Assurance |

| Material | Stainless Steel |

| Structure | Single Hole |

| Surface Treatment | Wire Drawing |

| Style | Modern |

| Outlet Style | Time-Lapse |

| Opening Way | Sensor Type |

| Pull Out Spray | Without Pull Out Spray |

| Number of Handles | Single Handle |

| Function | Induction |

| Purified Water Outlet | Without Purified Water Outlet |

| Hot and Cold Water | Cold |

| 360 Swivel | Not Rotatable |

| Installation Type | Wall Mounted |

| Suitable Water Pressure | 0.05-0.1MPa |

| Suitable Temperature | 0.1-70ºC |

| Inlet Pipe Diameter | G1/2 |

| Specification | 304 stainless steel, Wire drawing |

| Trademark | Shuaiziqi |

| Origin | Kaiping |

| Production Capacity | 50000pieces/Year |

Product Description

SUS304 angle valve: size and specification can be configured arbitrarily

Installation steps

1. This faucet is suitable for use under the conditions of water pressure 006-10ma and water temperature 090.2. Before installation, the pipeline must be flushed with water to ensure that the sediment and other sundries in the pipeline are cleaned.3. Cover the faucet inlet with a decorative cover, wrap the thread with a raw material belt, and then screw it into the installation nozzle.4. Open the pipeline valve and check whether the connection part is sealed well. If there is no water, the installation is successful.